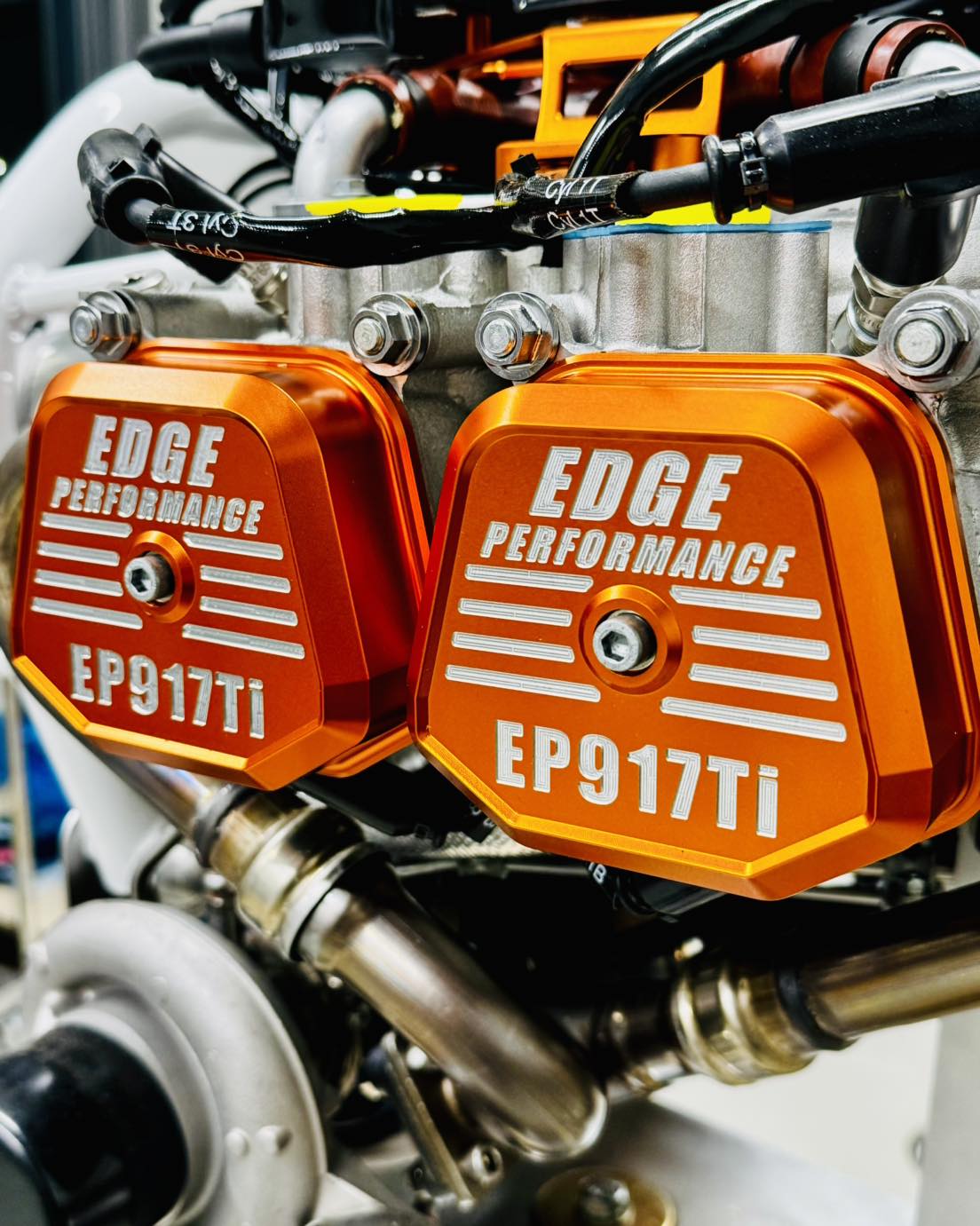

EP917Ti

– Technical Engine Data

- Engine Displacement: 1352ccm3

- Bore x Stroke: 84.00×61.00mm

- Gearbox reduction ratio: 2.54:1

- Engine weight w/gearbox w/overload clutch, turbocharger, intercooler, exhaust system: 81.5Kg / 179.6lb

- Engine suspension frame: 2Kg / 4.4lb

- External Alternator: 3Kg / 6.6lb

- Air Guide Baffle: 0.4Kg / 0.8lb

- Fuel Pump Assy: 1.6Kg / 3.5lb

- Power output: 160HP (118Kw)/180HP (133Kw) 224Nm (113ft/lb) @ 5800rpm

- Torque: 224Nm (165ft/lb)@ 5800rpm

- PTO Torque: 569Nm (420ft/lb)@ 5800rpm

- Fluids: 50/50 Glycol/Water mix (silicate free), Aeroshell Sport Plus 4

– Operating Limitations

- Idle speed: 1800rpm

- Max rpm: 5800rpm (max 5 minutes)

- Max cont. rpm: 5500rpm

- Cruise rpm: 4000-5400rpm

- Critical Altitude: MAT max 50°C – 15.000’ Note – The max.cont. power is available up to critical altitude

- Operating Altitude: 23.000’

- Acceleration: -0.5G (max 5 seconds)

- Static roll angle: 40°

- Intake air temp: 50°C (120°F)

- Manifold pressure: Max 51In/Hg (Max.cont. 42In/Hg)

- Fuel: AKI 93 / 98 RON / E10 (Alternatively AVGAS UL91/100LL)

- Oil pressure below 3500rpm: 0.8-5Bar (11.6-72.5psi)

- Oil pressure above 3500rpm: 2.0-5Bar (29-72.5psi)

- Oil temp ground ops: 100°C (-4 – 212°F)

- Oil temp: min 50°C before max power, limit 130°C (120 – 266°F)

- Coolant temp ground ops: -20 – 90°C (-4 – 194°F)

- Coolant temp normal operations: 40 – 120°C (104 – 248°F)

- Fuel pressure: 2.5-4.0Bar (36-58psi)

- EGT limits: 950°C (1742F°)

- EGT-split: 200°C below 3ltr/hr, 500°C above 3ltr/hr

- Ambient temperature: Ground -20 – 50°C (-4 – 120°F)

- Ambient temperature: Flight -40 – 50°C (-40 – 120°F)

- Oil consumption: Max. 0.06 l/h (0.13 liq pt/h)

– Description & Key Features

- Fully sequential ignition and fuel control

- Closed loop EGT

- Adaptive knock control

- High Boost / Low Boost function

- CAN data stream

- EFIS compatible

- 4-Cylinder

- 4-stroke liquid-/air-cooled engine with opposed cylinders

- Dry sump forced lubrication with separate oil tank, automatic adjustment by hydraulic valve tappets

- Redundant electronic fuel injection and ignition

- Fully programable dual Engine Management System

- Dual alternators (15/35Amp)

- Electric starter (12 or 24 volt)

- Propeller speed reduction gearbox (2.54:1)

- Flow optimized equal lenght air intake system / intercooler

- Turbocharger / stainless steel exhaust

- TBO 1,200 hrs

- Maximum operating altitude 23.000 feet

- Maintenance in accordance with the Rotax® 915iS LMM/HMM. (Supplementary EP917Ti MM

• Tested To 202HP

• Dual ECU, Fully Redundant, Full FADEC

• CAN Aerospace – Communicates with Garmin, Dynon…

• Same Mounting Points And Dimensions As 915/916iS

• Sea Level Power Up To 15.000’

• Service Ceiling 23.000’

• Fully Sequential Fuel & Ignition Control

• Closed Loop EGT & Injector Control

• Adaptive Knock Control For Max Efficiency

• Fully User Tunable And Programmable ECU (2D/3D/4D)

• In-Flight High / Low Boost Setting

• Based On The Already Prooven 915iS

• Gyrocopter, Fixed wing, Helicopter, UAV, Airboat

• TBO 1200 Hours (Expected 2000 Hours)

• Available With Hyd.Governor Intake & Stubby Intake